Product Introduction

-

JP

1004A machine that cuts products into cube shapes

Collaborative Robot with Operators

With a variety of lineups Wide range of applications

With a variety of lineups Wide range of applicationsOffering a variety of JP series lines to suit various environmental conditions.

×-

Components and Production Form

Consists of primary and secondary machines, with each comprising an entry conveyor, cutting unit, exit conveyor, product transfer device, and control box. Additionally, it is configured as 2 groups of 1 team each, operating with 2 people in 1 team.

-

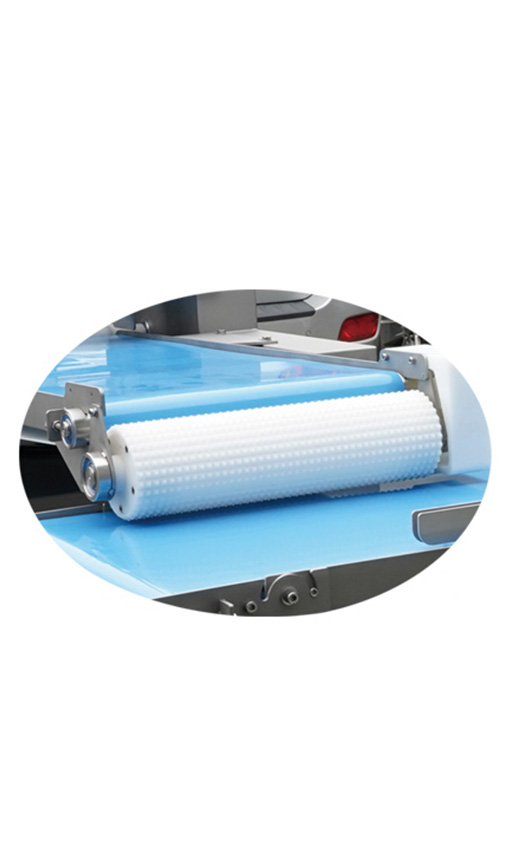

Cutting Method

The primary machine cuts in the length direction of the material, while the secondary machine cuts into cube shapes.

-

Device for production efficiency

The passing device of the secondary machine plays a role in aligning the cut materials in front of the operator, aiding in the operator's production efficiency and facilitating the smooth progress of the production process.

Machine Specifications

- Product

-

-

Structure

Stainless steel angle pipe, stainless steel bending structure

-

Conveyor Belt

Polyurethane belt

-

Operating Voltage

3-Phase 380V

-

Power Consumption

0.75KW * 2EA

-

Structure

- 1st Machine Size

-

-

Width

2,288mm

-

Height

700mm

-

Length

1,391mm

-

Width

- 2nd Machine Size

-

-

Width

2,710mm

-

Height

700mm

-

Length

1,110mm

-

Width

- KNIFE

-

-

Outer Diameter

Ø 170

-

Inner Diameter

Ø 28

-

Material

420J2

-

Thickness

1mm

-

Outer Diameter

- Yield / Operator

-

-

Yield

200kg / 1hr

-

Operator

2 persons

-

Yield

-