-

JP77

JP77Automatic Poultry Slicer A machine that precisely cuts chicken into the desired weight and pieces using a 3D mold. The chicken is spread out and placed into the mold, which then progresses forward, cutting the meat with a circular blade.

-

JP77S

JP77SSmall-sized Automatic Poultry Slicer A model downsized from JP77, optimized for installation in compact spaces.

-

JP77 - 1

JP77 - 1Meat(Deboned Chicken Thigh),Breast Slicer A machine for cutting meat(deboned chicken thigh) and chicken breast. It can be operated by 1-2 people, reducing labor costs.

-

JP7

JP7Wing Cutter Consists of a mold section for inserting wings, a tip cutting section, a wingette and drumette cutting section, and a conveyor for discharging the cut materials. Each cut section is separated and collected through the conveyor and separation chute to complete the product. They can be collected in P-boxes or lifted by installing a vertical conveyor.

-

JPAT23

JPAT23Plastic Wrapping Removal Machine This is a machine that automatically removes packaging from raw materials. It cuts the packaging containing the raw materials and evenly deposits the contents onto the conveyor. After discharging the raw materials, the remaining plastic packaging is automatically collected in one place via the machine chain, making disposal easy and eliminating the need for additional labor.

-

JPCON

JPCONCone Disassembly Machine A fully automated machine designed to secure chickens on a cone-shaped support and transport them automatically, allowing workers to efficiently disassemble them. With automatic movement of the chickens, worker movement is minimized, and the efficiency of disassembling each part is maximized. Equipped with safety sensors and control systems to ensure worker safety,

it can be integrated with a C/V (conveyor) system for an efficient production line.

※C/V installation is separate. -

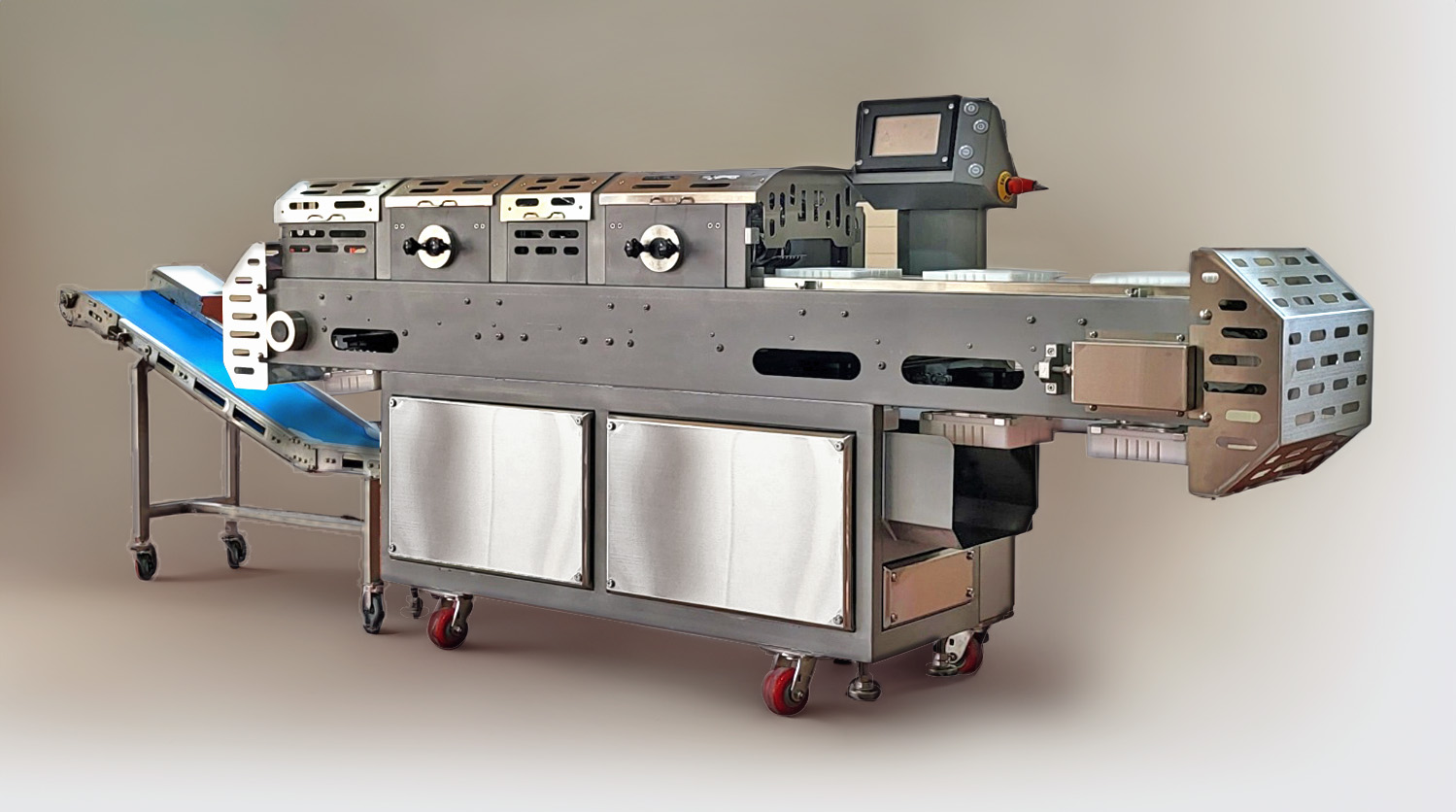

JP450

JP450Slicer JP450 is equipment primarily used for slicing chilled meat such as duck, chicken, beef, pork. It is equipped with an input conveyor(to put the product into the machine), rounded cuttingboard that supports the rounded cutting knives and an output conveyor that discharges finished product.

-

JPD7

JPD7Drumstick Scores Machine This machine is designed to make scores in the drumstick to allow for better seasoning penetration.

-

JPG7

JPG7Gizzard Cutter The machine consists of a Knife section for cutting the gizzard, a Mold section for securing the product, and a Chain Drive section for moving the mold, making it suitable for cutting chicken gizzards.

It can cut a large quantity of gizzards with one operator, making it convenient for mass production and cost saving. -

JPN720

JPN720Neck Skin Remover A machine developed to easily remove the neck skin of chickens, it enables maximum efficiency with minimal manpower.

-

JP201

JP201Jeriky Slicer It is a machine that cuts beef jerky vertically using multiple blades.

-

JP501

JP501Slicer It is equipped with a single phase motor, input conveyor, output conveyor and a cutting station. The guides on the input conveyor serve to position and guide the material. The cutting unit consists of a blade, shaft, body, scraper, cutting board, and board scraper, mainly used for cutting meat. It's also possible to purchase two machines and use them for the operation.

-

JP1004

JP1004Slicer Consists of a primary machine that cuts in the length direction of the material and a secondary machine that cuts in a cube shape. The primary and secondary machines are composed of an entry conveyor, cutting unit, discharge conveyor, product transfer device, and control box. There are two machines in a group and two people work together as a team.

-

JP2102

JP2102Longitudinal Breast Meat Slicer JP2102 consists of a lower belt to insert chicken breast and meat(deboned chicken thign), an upper belt to hold the product in place, a knife section, a control section to control the thickness of the product(+5mm form standard thickness) and an operating section.

PRODUCT

Company Products